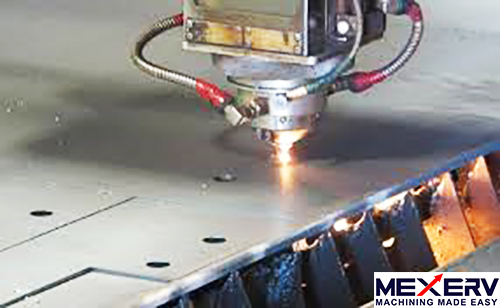

Laser Cutting

The Laser cutting process employs a high-power laser which is made incident on the required work piece, guided by optics and computer numerical control (CNC). The equipment uses a control system for motion which follows a CNC or G-code of the pattern that is to be cut or made onto the required material. The laser beam is focussed accordingly and burns or vaporises the material or is blown away by a jet of gas to leave surface finished edge.

Laser Cutting Methods

Depending on the material to be cut the cutting methods used differ

Fusion cutting (high pressure cutting):

- The material will be fused with the energy of the laser beam.

- Nitrogen gas at high pressure of up to 20 bar, is used to wipe away the molten material. It also prevents splashes on the focusing optic devices.

Oxidation of the cutting edges is primarily avoided in this method and is used with stainless steels, aluminium and their alloys.

Oxidation cutting (laser torch cutting):

- The laser beam heats the material up to combustion temperature.

- Oxygen gas at a pressure of up to 5 bar is used for oxidation of the material and to drive off the slag. It also prevents splashes on the focusing optic devices.

- The energy for the cutting process is largely derived from the exothermic reaction of the oxygen with the material.

- This cutting method is the fastest and is used for the cutting of carbon steels in an economical manner.

Common Applications of Laser cutters:

- S

- Metals

- Reflective Metals

- Medical Sciences

- Engraving and Marking

- Silicon